28/01/2026

FIREFLY’s electrochemical toolbox: progress and challenges

A preliminary analysis before completing the first Integrated Life Cycle Sustainability Assessment [ILCSA]

The composition of a DeNOx catalyst, for instance, shows it can contain significant amounts of Ti, but also W, V – metals of strategic importance and listed by the European Commission as critical and strategic metals, whose supply chain is under pressure. Under current methods, recovering them is costly in addition to pollution. But FIREFLY is taking steps to change that by developing a flexible set of electrified technologies to recycle spent catalysts using renewable electricity. The main objective is to demonstrate these technologies can cut carbon emissions, while reducing reliance on imported metals and making recycling economically viable.

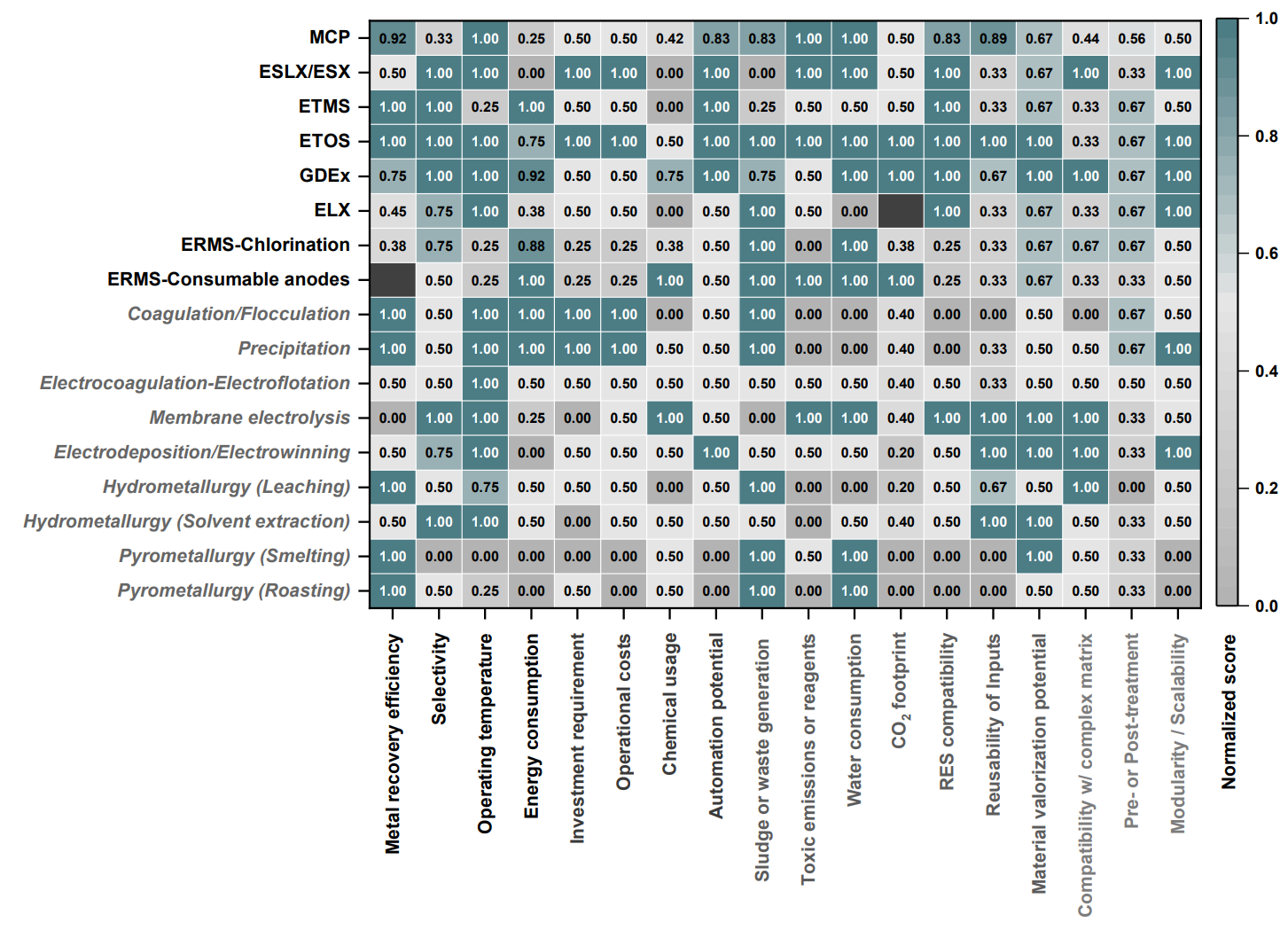

Which technologies can be found in the toolbox and what is working so far

Mechanochemical processing (MCP) uses high-energy milling to facilitate metals extraction/leaching. MCP delivered:

- VITO-Pd/C: 100% palladium recovery

- ENGIE DeNOx: Nearly complete recovery of vanadium and tungsten

- Johnson Matthey Pd/C: about 73% of Pd extraction

Electro-driven solvoleaching (ESLX) dissolves metals in organic solvents and regenerates chemicals electrochemically.

- ESLX closed the loop by regenerating copper chloride, the oxidising agent and achieved 75-98% Pd leaching for VITO-Pd/C, followed by 80% extraction, 87% copper scrubbing, and 81% stripping

Electro-leaching (ELX) uses electricity to create oxidants that dissolve metals in mild electrolytes. ELX proved effective for Pd, Pt and V recovery using deep eutectic solvents (DES). It achieved:

- ENGIE DeNOx: 80% V, 77% Mo, 22% W

- SOLVA-MM composite: 80–85% V, ~60% Mo, 40–55% Ni and Co, 60–65% Cu

- Johnson Matthey Pd/C: 57% Pd, ~50% Pt

In some cases, metals were deposited directly on electrodes, simplifying downstream processing step.

Gas-diffusion electrocrystallisation (GDEx) recovers metals from solution by reducing gases at a gas-diffusion electrode. GDEx achieved:

- JM Pd in acetonitrile stream: nearly 100% Pd removal

- JM Rh in DMF: 45% Rh removal (low conductivity challenge)

- (MCP) VITO-Pd/C and (MPC) JM-Pd/C leachates: 92-99% Pd removal (Fe remained in solution)

- (ELX) JM-Pt/C leachate: 87% Pt removal (Impurities remained in solution)

Electrochemical recovery from molten salts (ERMS): high-temperature electrolysis for refractory materials. ERMS results:

- JM-Pt/C ash: ~30% Pt converted and recovered as metallic Pt

- ENGIE DeNOx: 60% W conversion, 40% V conversion

- Synthetic nitrides (ZrN and VN): Successful anodic dissolution and recovery of Zr and V on cathodes

Electrochemical transformation (ETMS/ETOS) converts metal oxides or organics into reusable forms.

- ETMS has shown promising lab-scale results, 76% of the overall current efficiency for the process of TiO2 electrolytic reduction to Ti

- On the other hand, ETOS focuses on converting organic residues into reusable compounds and enables the one-step synthesis of Pd/TiO2 It has shown >99% Pd recovery from Pd in acetonitrile waste stream.

Solvent replacement strategies support these processes, enabling membrane-based exchange for some organic streams. Corrosion and incompatibility issues, however, persist. The ionic liquid-based antimony recovery achieved successful electrodeposition with a purity of about 98%.

These results show that electrified recycling route is technically viable, with specific processes, such as MCP, GDEx and ELX ready for scale-up. Other technologies require refinement, especially for complex or dilute streams. The encouraging update is that recovered metals are already being used to make new catalysts and tested in biomass conversion and lignin depolymerisation processes.

During the upcoming stages, FIREFLY partners will focus on integration, scale-up and validation in real industrial settings. In fact, partners at 6TMIC have recently released the first outcomes of modelling efforts for three electrochemical technologies proposed by FIREFLY: ELX, GDEx and ETMS. By simulating these processes under different conditions, partners will define operating strategies and prepare digital tools for process optimisation.