28/01/2026

FIREFLY selects technologies for small-scale pilot

Europe’s chemical industry depends on catalysts made with metals such as palladium and platinum, most of which are imported. With supply chains under pressure, EU-funded project FIREFLY is exploring electrified recycling routes powered by renewable electricity. A recent sustainability assessment offers insight into which processes could deliver the best environmental and economic performance.

Choosing the most sustainable recycling routes

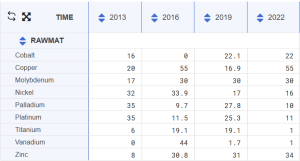

Current recycling methods are energy-intensive and often miss the economic aspect, leaving large quantities of spent catalysts unused. European Commission’s JRC and Eurostat, as well as Johnson Matthey’s 2025 Report indicate deficit of secondary supply for most of the metals used in the chemical industry.

Contribution of recycled materials to raw materials demand – end-of-life recycling input rates (EOL-RIR): Source: Eurostat Data Browser

FIREFLY aims to address this gap by combining (electro)chemical processes powered by renewable electricity with predictive digital decision-making tools. This approach reduces environmental impact and improves decision-making compared to traditional recycling routes.

Earlier this year, FIREFLY partners published a comparative study on electrified metal recovery technologies and conventional approaches such as pyrometallurgy and hydrometallurgy. The analysis reviewed technical, economic and environmental indicators, including recovery efficiency, selectivity and energy use. Results showed FIREFLY processes like Electrochemical transformation in organic solvents (ETOS), Gas-diffusion electrocrystallisation (GDEx) and Electro-driven solvoleaching (ESLX)/Electro-driven solvent extraction (ESX) achieve high recovery yields while reducing environmental impact and enabling renewable energy integration.

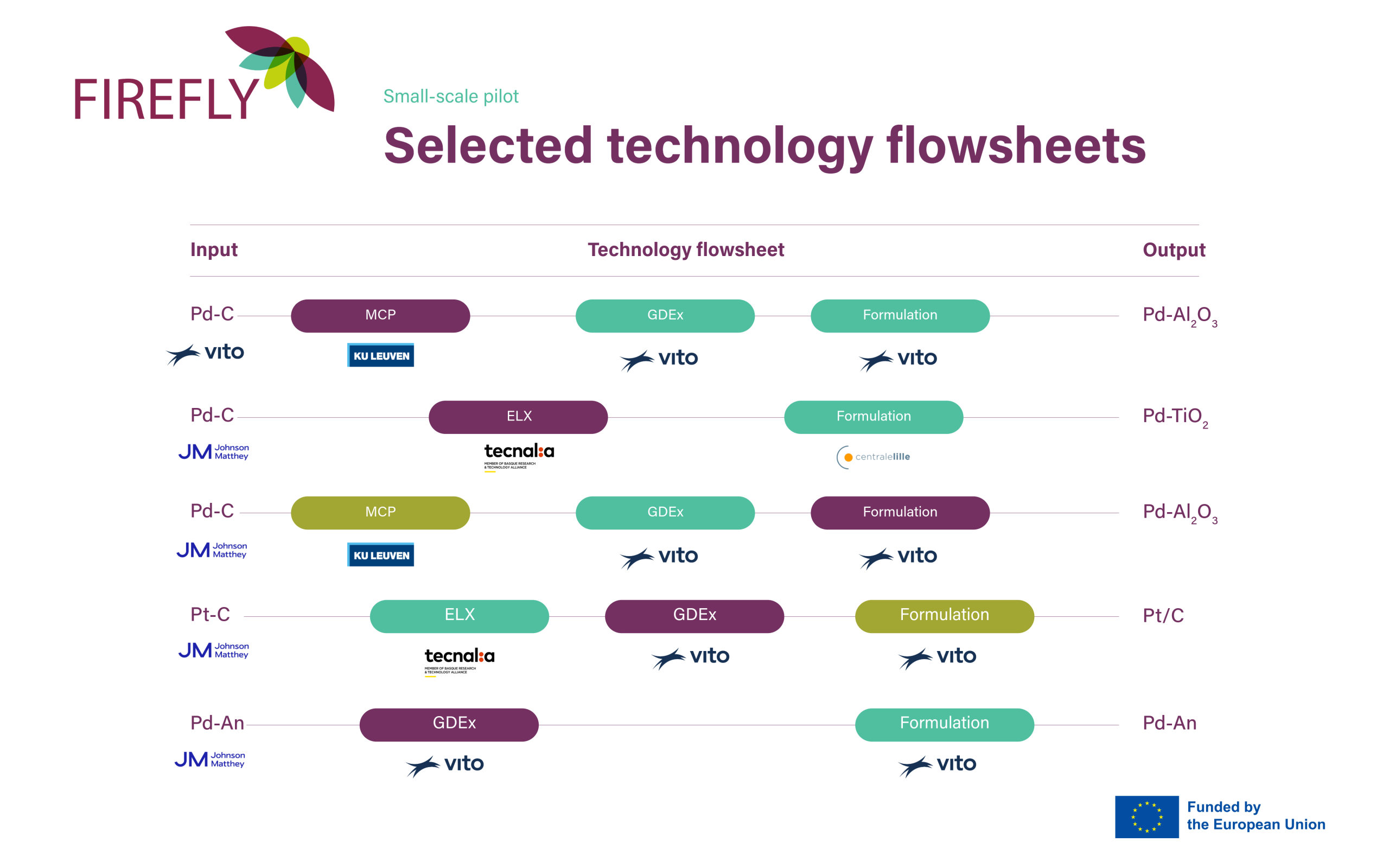

Building on this previous benchmarking analysis, the project completed more recently an Integrated Life Cycle Sustainability Assessment (ILCSA) for palladium-based waste streams. The analysis combined environmental and economic indicators to compare several recycling routes developed in FIREFLY:

- ESLX (Electro‑driven solvoleaching) by KU Leuven-SOLVOMET

- MCP (Mechanochemical processing) by KU Leuven-Group T

- GDEx (Gas-diffusion electrocrystallisation) by VITO-ELEC

- ETOS (Electrochemical transformation in organic solvents) by KU Leuven-MTM

Other technologies, such as Electro-driven solvent extraction (ESX) by KUL-SOLVOMET, Electrochemical recovery from molten salts (ERMS) by SINTEF, Electrochemical transformation in molten salts (ETMS) by KU Leuven-MTM and Electro-leaching (ELX) by TECNALIA were not included in the comparative LCA study due to several factors. They were evaluated separately at lab-scale using eco-design methods, instead.

This preliminary analysis outlined also the main environmental issues, briefly explained below:

- ESLX: high solvent consumption, additional waste treatment of contaminated solvents, gas emissions notably during catalyst shaping and formulation

- MCP (+) GDEx: mainly electricity consumption, gas emissions, acid use

- ETOS: large waste volumes, high impact for support material – TiO₂

From an economics perspective, coupling MCP and GDEx stands out, not exclusively for its higher Pd recovery rate, but also for its lower CAPEX and reduced OPEX.

The report showed that combining KU Leuven’s mechanochemical processing [MCP] with VITO’s gas-diffusion electro-crystallisation [GDEx] offers the best balance of performance and cost. Electroleaching [ELX], a technology proposed by TECNALIA, was also retained for its flexibility based on its energy consumption and technical performance. These routes will now be prepared for pilot-scale testing.