27/08/2025

A circular model for the chemical industry

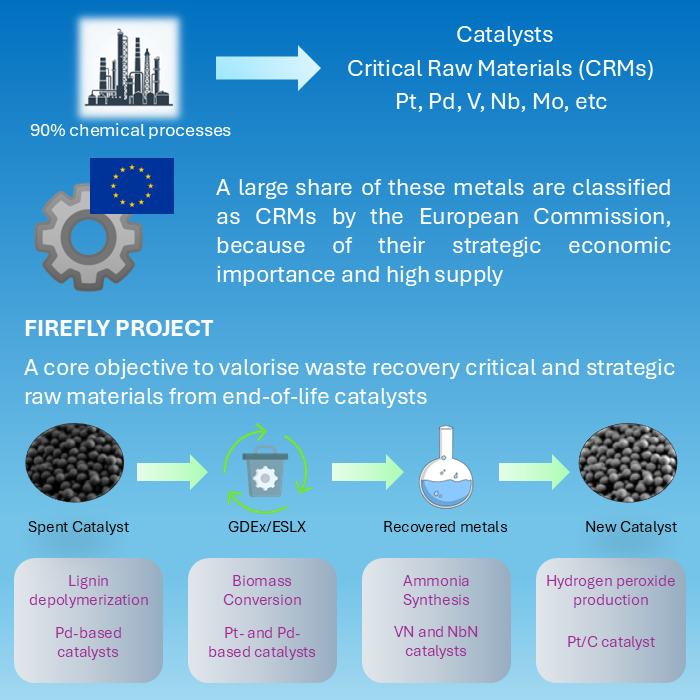

Catalysts are at the heart of the chemical industry, with around 90 % of chemical processes and 60 % of industrial products relying on them. Their ability to accelerate reactions, enhance efficiency, and improve selectivity makes them indispensable for producing fuels, plastics, fertilizers, pharmaceuticals, and countless other products. However, their critical role also makes the industry vulnerable.

The catalytic activity of many industrial catalysts depends on metals that act as active sites for chemical reactions. A large share of these metals are classified as Critical Raw Materials (CRMs) by the European Commission because of their strategic economic importance and high supply risk. Europe, while being a global leader in catalyst technology, is also one of the largest consumers of Platinum Group Metals (PGMs). With the competitiveness of the European chemical industry increasingly threatened by raw material supply shortages, boosting domestic metal recycling and reducing dependence on imports is becoming a strategic priority.

A core objective of the FIREFLY project is to valorise waste streams by recovering critical and strategic raw materials from end-of-life (EoL) catalysts. To achieve this, a consortium of research institutions and industry partners has been developing and optimising flexible technologies within the electrochemical toolbox and catalyst synthesis.

After 30 months of work, the research teams successfully demonstrated the recovery of valuable metals from industrial waste streams using advanced processes such as Gas-diffusion Electrocrystallisation (GDEx) and Electro-driven Solvoleaching (ESLX). The recovered metals were then repurposed, either directly as (electro)catalysts or as precursors for synthesising new catalytic materials, showcasing a sustainable pathway for resource efficiency in the chemical industry.

By month 30 of the FIREFLY project, partners had developed over 50 catalyst formulations, with more than 15 batches fully characterised and distributed for testing in real-world applications. These catalysts are being evaluated across four demonstration cases: lignin depolymerisation, biomass conversion, electrochemical ammonia synthesis, and electrochemical hydrogen peroxide production:

- Lignin depolymerisation: VITO-CAST developed Pd-based catalysts supported on alumina (Al2O3) and silica (SiO2). These catalysts were shaped to improve porosity, and selected formulations were scaled using GDEx and ESLX leachates.

- Biomass conversion: CLILLE focused on Pt- and Pd-based catalysts supported on titanium dioxide (TiO2), activated carbon and carbon nanotubes. Their objective focused on refining surface functionalisation techniques to improve metal dispersion and enhanced surface properties.

- Ammonia synthesis: Atmonia developed a thermal treatment process to achieve the nitridation of metal powders such as V, Nb, and Ta. Despite scale limitations, the team successfully synthesised VN and NbN catalysts. Further analysis on the use of metal oxides as catalysts suggested a partial closure of the recycling loop.

- Hydrogen peroxide production: VITO-CAST synthesised Pt/C catalysts using both GDEx-derived metals and commercial precursors. For this application, characterisation of the catalysts revealed the presence of trace impurities, highlighting the need for additional purification steps.

The development process was reiterative and collaborative, with continuous input from testing partners helping to refine catalyst formulations. This work not only validates the technical feasibility of using recovered metals in catalyst production but also opens pathways for broader integration within the FIREFLY project.