26/06/2023

Gas-diffusion electrocrystallization

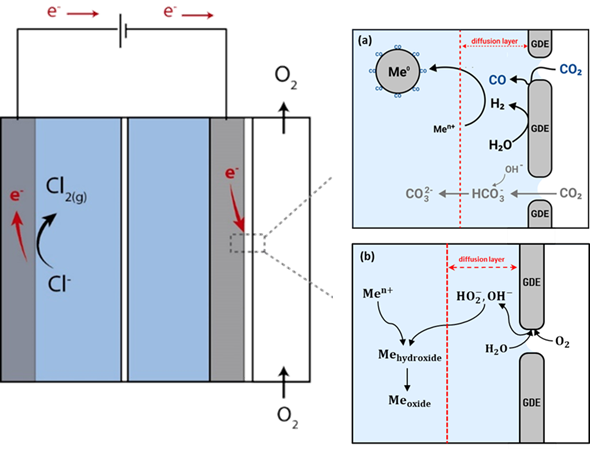

Gas-diffusion electrocrystallization (GDEx) is an electrochemical technology developed at VITO, Belgium. GDEx aims to recover a range of valuable elements from leachates and extractant solutions. During GDEx experiments, a rapid one-pot process takes place at the three-phase junction between a porous electroactive material, an aqueous electrolyte, and a gas (e.g., air, O2, CO2)—in a so-called gas-diffusion electrode (Figure 1). All the required chemical reagents which will react with the targeted elements are generated in situ from the electrochemical reduction of the entry gas.

Figure 1. Schematic representation of the GDEx process

In the framework of the FIREFLY project, the GDEx team at VITO has been performing a series of experiments related mainly to Task 3.1 of Work package 3 (WP3) – R&D and optimisation of flexible technologies in the electrochemical toolbox and catalyst synthesis. The team has undertaken the preparation of various synthetic solutions containing Vanadium (V), Tungsten (W) and Molybdenum (Mo) elements to investigate their precipitation and recovery conditions. Experiments showed that a precipitate can be obtained under specific conditions.

Additionally, samples have been received from ENGIE, Tecnalia (TEC) and Solvakem (SOLVA). The ENGIE sample, originally derived from a spent catalyst, was delivered in solid form. Consequently, the researchers at VITO undertook a series of processing steps including milling/roasting and leaching to obtain a leachate and selectively recover the targeted metals (V, W and Mo) using GDEx. Similar processing has been carried out on the leachates provided by TEC. It is still premature to assess the effectiveness of the GDEx in treating these leachates containing W, V and Mo. The third sample – containing vanadium pentoxide (V2O5) was provided by Solvakem in solid form.

The forthcoming plans include the following actions:

- Firstly, the VITO team will continue working with synthetic solutions containing V, W and Mo to gain better understanding, optimise and reproduce the recovery rate of these elements through GDEx.

- Secondly, the GDEx process will be applied on the leachate derived from ENGIE’s sample, which will contain the aforementioned elements, among others. The objective is to selectively recover the desired elements.

- Thirdly, the plan is to send the solid V2O5 from SOLVA to Catholic University of Leuven (KU Leuven) for rapid processing through mechanochemical milling.

- Meanwhile, the researchers at VITO are looking forward to receiving additional samples from KU Leuven and Johnson Matthey (JM) which contain platinum group metals (PGMs). These samples will undergo further treatment by GDEx.

The first scientific publication of the FIREFLY project

Breaking the ice, the GDEx research team ‘signed’ the first scientific publication of the FIREFLY project. Titled ‘Synthesis of platinum group metal nanoparticles assisted by CO2 reduction and H2 cogeneration at gas-diffusion electrodes’, the manuscript has been recently accepted and it is freely accessible online as an open-access publication in the journal ‘RSC Sustainability’ (O. Martinez-Mora, G. Pozo, L. F. Leon-Fernandez, J. Fransaer and X. Dominguez-Benetton, RSC Sustain. 2023, 1, 454-458). The publication can be accessed through the following link: Synthesis of platinum group metal nanoparticles assisted by CO2 reduction and H2 cogeneration at gas-diffusion electrodes – RSC Sustainability (RSC Publishing).