18/08/2025

Potential environmental benefits of valorisation routes

Simply by looking at the project’s concept, one can understand FIREFLY is designed and built to support the sustainable evolution of the catalyst-based chemical industry, towards its electrification and reduced third-party dependence on metals and fossil energy by the development of: i) Electro-driven technologies for metal recycling from spent, waste, and off-specification catalysts available in Europe; ii) Efficient integration of renewable electricity; iii) A digital tool for predictive decision-making; iv) Production of (electro)catalysts for innovative (electro)chemical processes that overcome traditional production associated with high operating conditions, greenhouse gas emissions and lack of circularity.

But what if we told you there’s more than the concept leaks at first sight? Researchers at TECNALIA have recently presented their Integrated Life-cycle Sustainability Assessment (ILCSA) and Roadmapping. This study aims to identify routes to achieve a near-zero-waste approach. It evaluates the best available technologies to recover metals remaining in spent catalysts after FIREFLY’s main recovery processes.

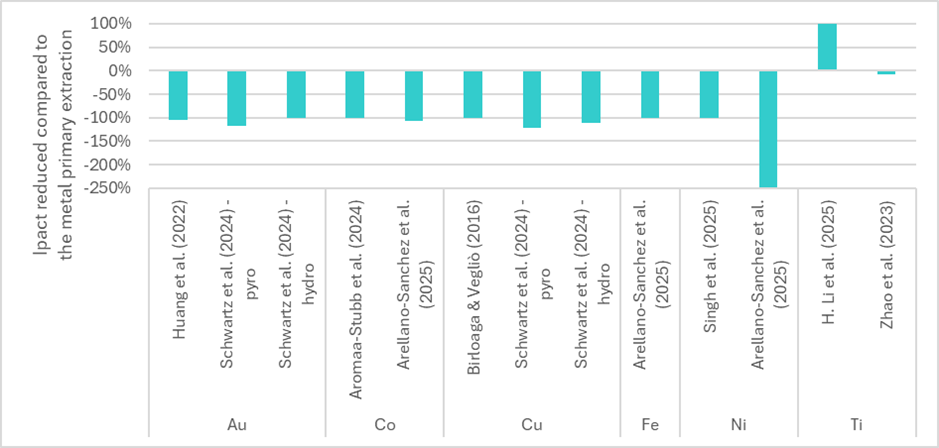

Their study includes a detailed analysis of spent catalysts from project partners: Johnson Matthey, SOLVAKEM, ENGIE-LAB, VITO, ATMONIA. It identifies the most valuable non-target metals for each catalyst, based on their abundance and economic value: Au, Ti, Cu, Ni, Fe, Co, Ru. For each metal, Tecnalia have conducted a comprehensive literature review of recovery technology, compiling Life Cycle Inventories [LCIs] and the impact has been calculated using the Product Environmental Footprint [PEF] methodology. These results have been particularised for FIREFLY’s technologies by individually documenting the quantity of recovered metal and the unextracted ones remaining in the waste streams.

Despite various gaps in environmental data for some metals and technologies that are hindering the comparison, results show that:

- Tertiary (recycling) extraction generally has a much lower environmental impact than primary extraction.

- Neutralising chemicals, rather than treating them as hazardous waste, significantly reduces environmental impact, especially for freshwater ecotoxicity.

- For specific metals, the best recovery technology is identified (e.g., Arellano-Sanchez et al. for Co and Ni, Schwartz et al. for Cu and Au, Zhao et al. for Ti).

The outcomes of the ILCSA provide a roadmap for integrating the most sustainable recovery technologies into the FIREFLY process and underscores the importance of data-driven decisions for future process optimisation.

Recycling reduction impact compared to primary metal extraction