29/08/2025

FIREFLY launches the first draft of its predictive tool for RES-powered electrochemical processes

The innovations brought by FIREFLY are expanding beyond the electrochemistry sector. Project partners are developing a new generation of digital tool that blend electrochemical innovation with the power of artificial intelligence. The core of this concept is a web-based predictive application designed to provide greater insight into the electrochemical processes and the sites using target catalysts (thus creating spent catalysts) and also to help users optimise catalyst recycling processes.

Developed by Inlecom Innovation (INLECOM), the tool features machine learning, process optimisation and geospatial intelligence in a modular and user-friendly application. It was designed and built to help researchers, engineers and industry stakeholders make informed, data-driven decisions about recycling processes and promote a true circularity for the catalyst usage.

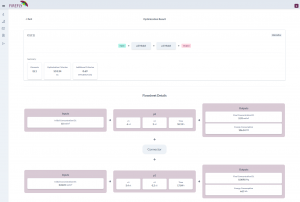

The predictive tool is built around three complementary functionalities that allow users to simulate and optimise complex recycling scenarios within a few clicks:

- Prediction of individual technologies powered by machine learning models trained on data from the electrochemical processes. Users can input parameters for specific electrochemical processes to receive predictions on outputs and energy consumption.

- Flowsheet optimisation: based on user-defined objectives (such as energy minimisation or recovery efficiency maximisation), the tool can identify the optimal process flows for recycling specific catalysts.

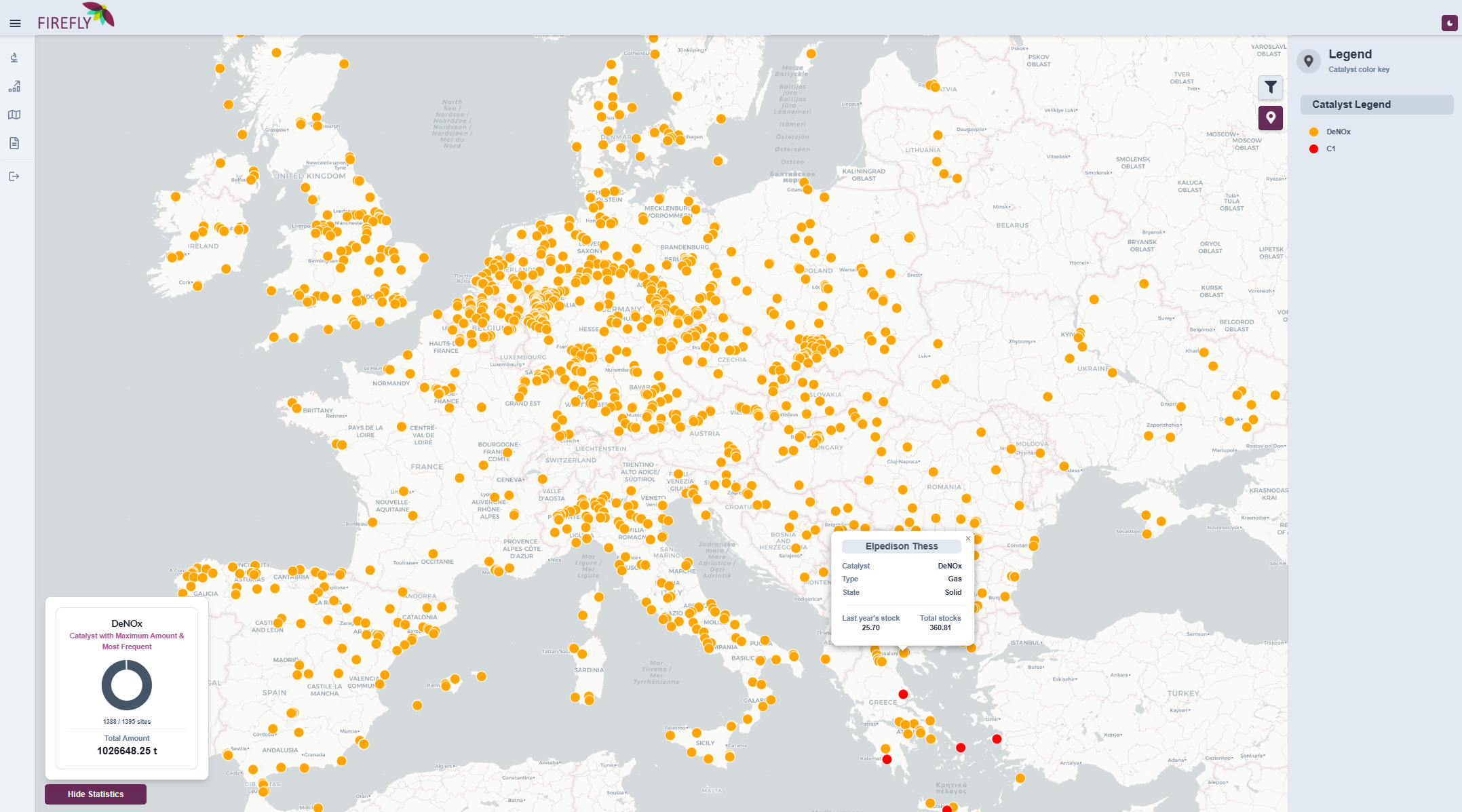

- Interactive map: a dynamic GIS interface allows users to explore the geolocation of spent catalyst stocks across Europe. Users are provided with the possibility to tailor their search, filtering by country, catalyst type, or even select custom areas to assess regional recovery potential.

- Flowsheet optimisation results

- Interactive map

Smart architecture and scalability potential

The tool’s architecture is designed for scalability and evolution over time, ensuring the application can integrate new data and models while also using user feedback to continuously improve its development.

The current version includes machine learning models for three real electrochemical processes: ETMS on TiO₂, GDEx on platinum group metals (PGMs) and ELX on spent DeNOx catalysts (trained on thousands of experimental data points), as well as simulated models to demonstrate future capabilities. The application is engineered to seamlessly incorporate new models or updated versions of current ones.

The tool also supports batch predictions and CSV exports, making it suitable for both exploratory research and industrial-scale analysis.

Initial feedback from project partners has been positive, and further validation is planned through pilot studies and real-world testing. Upcoming releases will integrate additional machine learning models, real flowsheets and expanded GIS data. The ultimate goal is to create a robust, scalable platform that supports the transition to a more circular, electrified and sustainable chemical industry.

Looking ahead: potential exploitation across industry

Beyond its technical capabilities, the predictive tool is positioned as a high-value digital asset with strong commercial potential. INLECOM is exploring several exploitation pathways, including:

- Offering the tool as a service to electrochemical manufacturers and catalyst recyclers.

- Partnering with consultancies and research institutes for validation and dissemination.

- Developing a tiered Software-as-a-Service (SaaS) model for broader market access.

© visuals: INLECOM