07/03/2024

GDEx process – PGM cases in FIREFLY

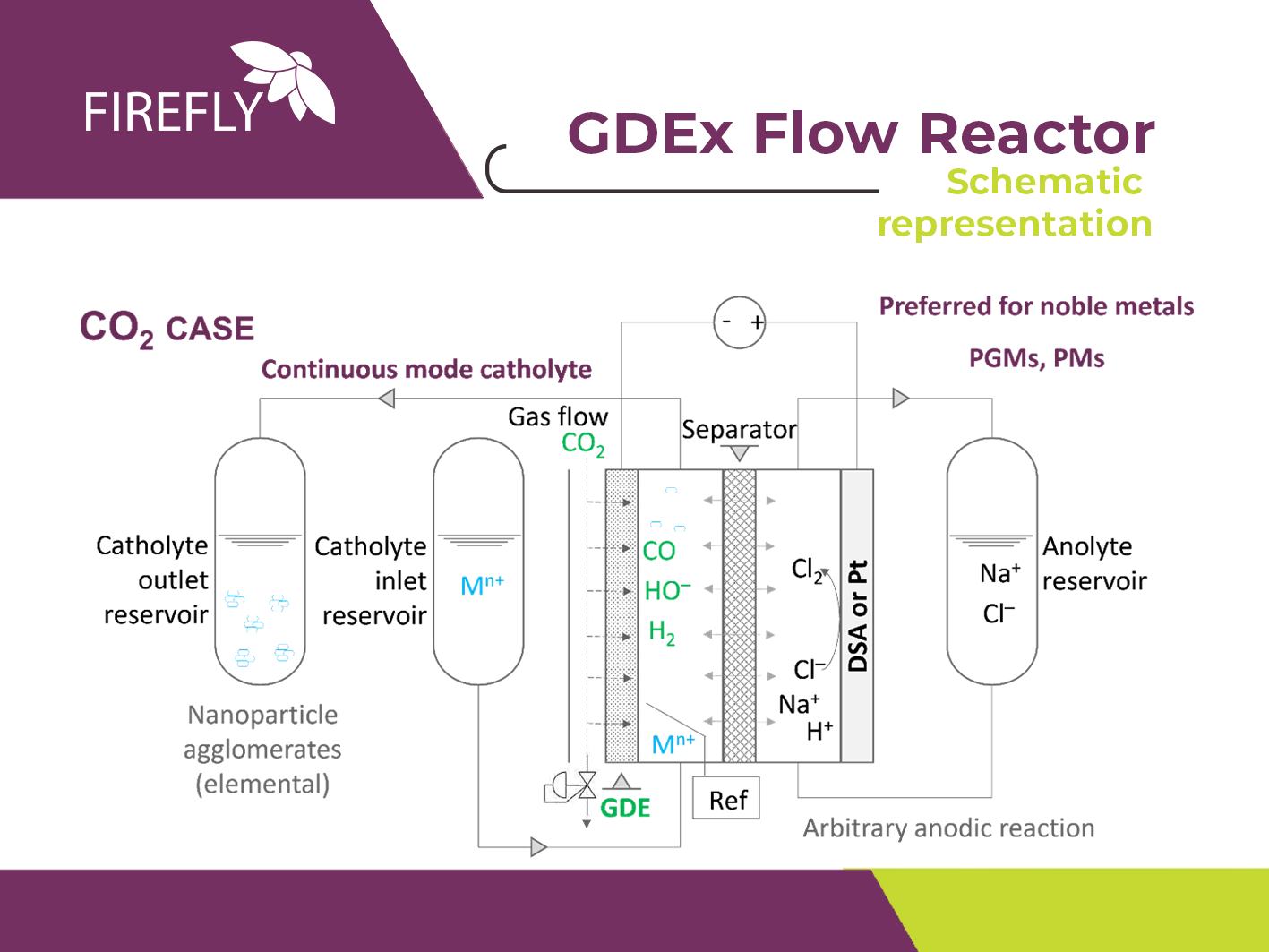

VITO has developed the proprietary Gas-diffusion Electrocrystallization (GDEx) process for the specific recovery of platinum group metals (PGMs), i.e., platinum (Pt), palladium (Pd) and rhodium (Rh) into nanoparticles (NPs). In the GDEx reactor, as illustrated in the schematic representation below, CO2 is reduced in a so-called gas-diffusion electrode (GDE) to CO. Simultaneously, the water reduction to H2 occurs. Both gases (CO and H2) will interact with PGMs ions in the solution. H2 will reduce the PGMs ions to their zero valent states, forming metallic PGMs NPs, while CO will interact with the newly formed NPs, inhibiting their growth, allowing us to obtain primary NPs of around 2-5 nm.

Schematic representation of the GDEx typical flow reactor

Discover our scientific publication in RSC

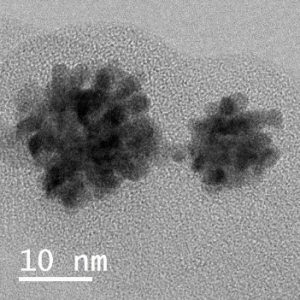

At the GDEx conditions – with high ionic strength of the supporting electrolyte (NaCl 0.5M) and local pH characteristics – these primary PGMs NPs will form bigger nanoclusters of around 10-30 nm. Supported PGMs nanoparticles can also be produced if the support (i.e., metal oxide NPs, carbon nanotubes) is added to the synthesis reaction. The GDEx process is effective in both aqueous and organic matrixes.

Pt NPs clusters synthesized using the GDEx process

During this phase of FIREFLY, R&D partners of work package 3 (WP3) have received waste, spent, or off-specification streams from different industrial partners to recover critical and strategic metals through several innovative electrochemical technologies. In Task 3.1, the GDEx team of VITO has received several waste streams, including streams containing PGMs in organic solvents from JOHNSON MATTHEY PLC (JM) as well as Pd in DBU and Pd in methanol from SOLVAKEM (SOLVA). Synthetic samples based on PGMs were investigated as a preliminary step before treating the real streams. Pt and Pt-Pd alloy NPs were prepared from synthetic solutions at room temperature using GDEx process and further characterised.

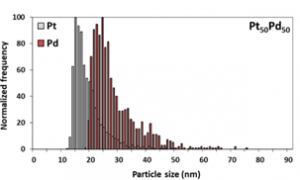

Among other characterisation techniques, GDEx team has implemented innovative single-particle inductively coupled plasma-sector field mass spectrometry (spICP-SFMS) to investigate the formation of Pt-Pd alloy nanoclusters.

Discover our scientific publication in MDPI Nanoparticles

Parameters such as spherical equivalent diameter, particle size distribution and particle number concentration were obtained from spICP-SFMS, the technique which overcomes the bottleneck of multi-element capabilities in conventional spICP-MS systems, as illustrated in the figure below.

Particle size distribution of Pt50-Pd50 alloy nanocluster determined using spICP-SFMS

Later, Pt NPs and Pt-Pd alloy NPs were sent to CENTRALE LILLE INSTITUT (CLILLE) for testing their catalytic activity in one of the demo cases of FIREFLY – chemical processing of biomass (Task 7.1 of WP7). Furthermore, a portion of the Pt NPs was sent to Task 3.4 – Synthesis, formulation and shaping of (electro)catalysts to impregnate Pt NPs on carbon. The formulated electrocatalyst will be later transferred to UNIVERSIDAD DE CASTILLA – LA MANCHA (UCLM) to test their catalytic activity in the demo case – electrochemical production of hydrogen peroxide (Task 7.2).

Our scientific publications based on the synthesis of PGMs using GDEx technology

- Titled ‘Platinum nanoclusters made by gas-diffusion electrocrystallization (GDEx) as electrocatalysts for methanol oxidation’, the scientific article is published in the journal ‘Materials Advances’ – The Royal Society of Chemistry (Martinez-Mora O., Leon-Fernandez L.F., Velimirovic M., Vanhaecke F., Tirez K., Fransaer, J. and Dominguez-Benetton X., Materials Advances 4(23) (2023) 6183-6191). This article is featured in the “Popular Advances themed collection” of the journal Materials Advances in 2023 and displayed on the front cover. The publication can be assessed through the following link: Platinum nanoclusters made by gas-diffusion electrocrystallization (GDEx) as electrocatalysts for methanol oxidation.

- Titled ‘Exploring Pt-Pd Alloy Nanoparticle Cluster Formation through Conventional Sizing Techniques and Single-Particle Inductively Coupled Plasma—Sector Field Mass Spectrometry, the scientific article is published in the journal ‘Nanomaterials’ (Martinez-Mora O.; Tirez K.; Beutels F.; Brusten W.; Leon Fernandez L.F.; Fransaer J.; Dominguez-Benetton X.; Velimirovic M., Nanomaterials 13 (2023)2610). The publication can be assessed through the following link: Exploring Pt-Pd Alloy Nanoparticle Cluster Formation through Conventional Sizing Techniques and Single-Particle Inductively Coupled Plasma—Sector Field Mass Spectrometry.