18/08/2025

Powering circularity with renewables: a FIREFLY study

Co-authors: Alberto Rodríguez Gómez [UCLM], Justo Lobato Bajo [UCLM] and Michel Vandenbergh [ENGIE LABORELEC], Hesam Ghadaksaz and Mohammed Nazeer Khan [VITO]

As a result of high energy and raw material utilisation, the current production and the recycling of catalysts mainly rely on processes that are neither sustainable nor economically feasible. With eyes set on the transition to a climate-neutral economy, the FIREFLY project aims to demonstrate how renewable energy can power the circular recovery of critical raw materials.

Work package 4 evaluates how renewable energy systems [RES] – photovoltaic panels, wind turbines and vanadium redox flow batteries, as energy storage systems, can support the energy demands of the electrochemical and non-electrochemical processes for metal recovery. The findings of UCLM researchers, based on experimental data from previous research phases, set a foundation for the design of a fully integrated renewable-powered recovery system.

UCLM researchers collaborated with the scientists developing the diverse recycling technologies, which allowed them to grasp the wide spectrum of applications and energy profiles:

- Electro-Leaching (ELX), developed by TECNALIA, uses mild electrolytes and in situ oxidants to dissolve metals like vanadium, molybdenum and platinum from solid waste. With recovery rates up to 98 %, ELX offers a scalable and eco-efficient alternative to traditional hydrometallurgy, achieving energy consumption below 100 kWh/kg under optimised conditions.

- Gas-diffusion Electrocrystallisation (GDEx), from VITO, enables selective metal recovery from liquid matrices using air or CO₂. It operates under mild conditions and achieves over 90 % recovery efficiency, with energy consumption ranging from 18 to 93 at lab-scale and 15 to 480 kWh/kg at pilot-scale depending on the input stream.

- Electrochemical Recovery from Molten Salts (ERMS), led by SINTEF, targets metals like vanadium and zirconium using high-temperature electrolysis. Despite operating at ~1000 K, it maintains low electrical energy demands (2–32 kWh/kg), making it a promising option for solid waste valorisation.

- Electrochemical Transformation in Organic Solvents (ETOS), developed by KU Leuven, recovers high-purity palladium from organic waste streams using a LED-assisted photoelectrochemical process. While energy-intensive, ETOS offers precise control over product quality and morphology.

- Mechanochemical Processing (MCP) and Electro-driven Solvoleaching (ESLX) provide complementary non-electrochemical routes. MCP enhances leaching efficiency through mechanical activation, while ESLX and its follow-up process, ESX, enable high-purity recovery of platinum group metals (PGMs), albeit with higher energy demands.

Their individual energy profiles, scalability and process integration potential serve as the foundation for the design of a robust, renewable-powered and storage system aiming to ensure continuous operation under fluctuating renewables inputs.

Addressing the intermittence of renewables with vanadium redox flow batteries

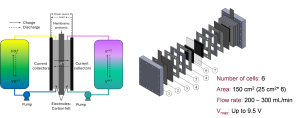

One of the key challenges in coupling these technologies with RES is managing the variability of solar and wind power. To address this, the FIREFLY team is integrating energy storage solutions, such as vanadium redox flow batteries [VRFBs], that can buffer supply and demand, ensuring stable operation even under fluctuating conditions. The batteries could be used to store energy when power generation rates are high [e.g. during sunny or windy days] and supply it when RES are unavailable – at night or during periods when wind is too weak to produce energy.

Not only do vanadium redox flow batteries perform reliably across seasons and under fluctuating energy profiles, but they provide additional features that make them suitable to power electrochemical metal recovery technologies such as modularity and the fact that the energy storages and power capacities are separated. They offer long lifespans [up to 20,000 cycles and over 10,000 h operations], low fire risk and a life cycle performance superior to lithium-ion batteries with a life span close to 20 years. When charged using solar and wind sources, VRFBs achieved energy efficiencies up to 80 %, which is higher than under constant current conditions. Their working performance remained consistent across seasons, recording only minor efficiency drops in winter. The only disadvantage which makes VRFBs unsuitable for electric vehicles is their rather low energy and power density. On the other hand, they proved to be better fit for stationary applications, such as storage of energy from variable renewable sources.

© UCLM: Scheme of an all-vanadium redox flow battery with the main parts: electrolyte tanks, a stack of electrochemical cell and the flow system

The study conducted by UCLM evaluated the possibility to couple VRFBs with four technologies developed under the framework of FIREFLY: Electro-leaching (ELX), Gas-diffusion Electrocrystallisation (GDEx), Electrochemical recovery from molten salts (ERMS) and Electrochemical transformation in organic solvents (ETOS). Each technology required specific VRFB configurations, from small lab-scale stacks [2-6 cells] to large parallel systems for pilot plants, according to the experiments conducted at lab scale.

Other design specifications for decentralised energy solutions suitable for electrochemical processes:

- Most technologies can be powered by small VRFB stacks (2-6 cells) at lab scale. However, medium-scale scenarios, particularly for energy-intensive processes such as GDEx and ETOS, require parallel configurations. In general, scaled scenarios need to consider TRL and real operational data of these technologies to avoid overestimations.

- Although solar output is more predictable than wind, solar-powered systems require larger battery capacities due to shorter daily autonomy. Profiles were derived from Ciudad Real (solar) and La Palma, Canary Islands (wind), representing typical southern European conditions.

- Wind-powered systems need larger turbines but smaller batteries in terms of the energy storage capacity, benefitting from longer daily generation windows.

- Conservative design assumptions ensure full energy independence from the grid supply.

Other partners, namely Engie Laborelec, are developing smart energy management systems to forecast energy availability, adjust process parameters in real time and optimise system performance. They are building tools essential for aligning energy generation, storage and consumption along sustainability and economic viability requirements.

The energy consumption profiles are now feeding information needed to design the integrated RES system and develop the predictive software. At a later stage, these efforts will be coupled into a modular, scalable platform for sustainable metal recovery, one that can adapt to different industrial context and resource availabilities.

Electrical design options and flexibility potential

The research goal of Engie Laborelec and UCLM is to identify the best options to adapt industrial processes to better align with the fluctuating nature of renewable energy sources. Central to their investigations stands the demand-side flexibility – with other words the ability of industrial processes to adjust their energy consumption in response to variables such as the electricity market signals or renewable energy availability. The need for electricity flexible capacities will increase in the coming years, fuelled by the growing share of variable Renewable Energy Sources [vRES] in the European mix.

Simulating greener production scenarios

To assess the potential of different technical solutions for a greener production by future recycling plants, the research team at Engie Laborelec simulated twelve scenarios based on a reference industrial process with a constant power demand of 10 MW and a maximum power dispatch of +2 MW/-2 MW. These scenarios included:

- Daily energy shifting possibilities, where energy consumption increases or decreases hourly by 20 %, optimising demand profile according to day-ahead market electricity prices.

- Onsite solar PV generation, where the factory load profile is reduced during sunny hours, reducing grid dependency by self-consuming the production of a 2 to 8 MWp PV plant.

- Battery storage, using energy storage to shift consumption and provide backup.

The technical scenarios were simulated for three locations: Belgium, South of France and South of Spain, chosen for their contrasting electricity price volatility and solar resources.

The study found that:

- Energy shifting by using process flexibility provides higher cost savings in countries with high daily electricity price volatility like Belgium.

- PV energy production is most profitable in regions where high electricity prices coincide with significant solar radiation resources.

- Battery storage, while technically viable, did not yield a positive business case under current market conditions as this technology is characterised by high capital costs and increased consumption due to cycling losses. In fact, the conclusions recommend prioritising process flexibility and PV integration over BESS options, the latter being considered when no internal process flexibility is available, when the system is not connected to the power grid, and in the case of a weak grid situation.

Although the study based its investigations on the FIREFLY technologies at lab scale, it provides valuable guidance for scaling up, emphasising the need for modular, adaptable systems capable of responding to dynamic energy markets and integrating renewables.

Renewables-based scenarios for future large-scale deployment

After outlining guidelines for future upscaling and highlighting opportunities to integrate renewable energy into catalyst recycling and synthesis, other partners in the FIREFLY consortium conducted a preliminary techno-economic assessment (TEA). This study, conducted by experts from VITO [SESAM and ADVANCE departments] in collaboration with LPRC , evaluated the project’s potential to transform and green conventional recycling pathways for PGMs. The assessment combined a detailed techno-economic analysis with energy systems modelling and strategic deployment planning at the European policy level. Its outcomes provide valuable insights into how FIREFLY can contribute to reshaping sustainable recycling approaches.

Techno-economic insights for palladium recovery

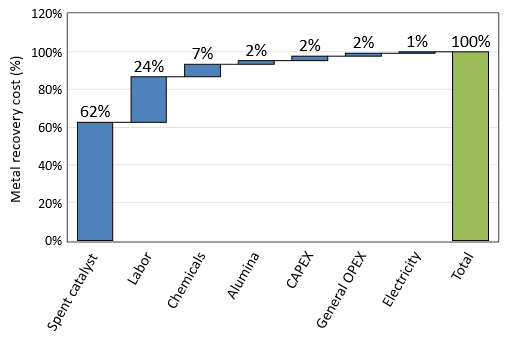

The preliminary techno-economic assessment of the flowsheet for Pd recovery from spent catalysts using electro-driven solvoleaching (ESLX), followed by catalyst reshaping, showed promising results. The total investment was estimated at €1.7 million, with operating expenses (OPEX) dominated by feedstock (62 %) and labour (24 %). Capital expenditure (CAPEX) was primarily associated with the electro-oxidation and solvoleaching units, which together accounted for 94 % of total CAPEX. The assessment was based on a treatment capacity of 100 tonnes of spent catalyst per year, operating for 7,884 hours annually under electrified conditions.

Metal recovery cost breakdown (relative) © VITO

Contrary to initial expectations, energy price fluctuations were found to have only a negligible impact on overall costs. This indicates that the FIREFLY project is well positioned to withstand volatility in the energy market with resilience. Preliminary analyses show that a 20 % increase in electricity prices would result in only a 0.2 % rise in total costs.

In contrast, feedstock pricing emerged as a critical factor: a 20% reduction in spent catalyst prices could lower Pd recovery costs by 14 %. Greenhouse gas emissions were estimated at 813 tonnes CO₂-equivalent per year, corresponding to approximately 1.1 tonnes of CO2-equivalent per kilogram of recovered Pd.

Novel PGM recovery technologies: benchmark against conventional recycling processes and impact on future energy use and emissions

The report features a detailed methodology to assess the impact of novel PGM recycling technologies on future EU energy use and emissions. The methodology includes scenario modelling, sensitivity analysis and benchmarking against conventional recycling processes such as pyrometallurgy and hydrometallurgy.

Current PGM production in Europe is primarily relying on recycling operations, dominated by smelting operations and clustered across facilities in Germany, Belgium and UK. These processes, while effective, are energy-intensive, consuming approximately 10 GJ/kg and emitting nearly 0.5 tonnes of CO₂-equivalent/kg. In contrast, primary PGM production, concentrated in South Africa and Russia, requires up to 460 GJ/kg and results in emissions reaching 32 tonnes CO₂. Beyond the environmental footprint and the limited resources, primary mining operations often imply difficult labour conditions and social risks. Given the possibility to recycle PGMs, and metals in general, indefinitely without compromising quality, the case for recycling becomes compelling. Simply considering the significant reductions of energy use and emissions footprint, coupled with the social and geopolitical implications of primary extraction, recycling offers a far more sustainable and responsible solution to secure EU’s PGM supply. Innovative technologies, such as gas-diffusion electrocrystallisation [GDEx], low-temperature leaching and plasma-assisted recycling, when powered by renewables, provide technological solutions to reduce energy use up to 90 % and nearly eliminate direct emissions.

The broader energy systems modelling suggests that advanced PGM recycling technologies such as those developed in FIREFLY could play a strategic, if modest, role in the EU’s energy transition. FIREFLY researchers based their projections on the premises that recycling could account for up to 90 % of PGM supply by 2050 – almost 70 % from the current recycling capacity of 21 %. Within this framework, FIREFLY technologies would replace up to 80 % of current recycling methods by 2050 (FIREFLY -Driven Clean Recycling scenario). Under a demand driven analysis approach, this scenario could:

- contribute to energy use reduction by almost 970 toe/year globally by 2050 which is almost 0.5 % of projected EU industrial energy demand.

- reduce emissions by 2.8 MtCO₂-eq annually.

While the energy and emission reduction impacts in the FIREFLY -Driven Clean Recycling scenario compared to that of the business-as-usual case, may appear limited under the EU territorial perspective, the benefits are substantial from the EU strategic perspective:

- reduced import dependency.

- enhanced circularity.

- resilience of EU industry value chains, due to the integration with low-carbon electricity deployment.

- improved supply security for metals vital to hydrogen technologies, such as platinum and iridium.

The strategic analysis confirms that the objectives initially established by FIREFLY align closely with the EU’s policy priorities:

- Critical Raw Materials Act (CRMA): 15 % CRM recovery target from EoL products

- Clean Industrial Deal (CID): supports low-carbon industrial innovation

- Circularity requirements for vehicle design and Waste Batteries Regulation

A 10 % reduction in PGM imports unlocked by recycling could save €3 billion in annual value across Europe. Market segmentation and SWOT analyses further identify regional opportunities and constraints, while spatial modelling highlights synergies between geothermal energy and catalyst recovery.

The study also investigated the geographical overlap between catalyst-intensive industries and geothermal resources across Europe. The scenario leverages mutual benefits: cogeneration to further reduce the operation costs and emissions of recycling processes; on the other hand, these industrial clusters can serve as local suppliers of catalysts required for advanced chemical processes: scaling and corrosion control, gas treatment, heat transfer efficiency. Beyond promoting circular business models, this integrated approach generates interesting industrial concept ideas that capitalise on regional development.